- Curved Lithium Polymer battery

- Fast Charge Polymer Battery

- Flexible Polymer Lithium Battery

- Ultra-thin Polymer Battery

/ Blog / Battery Knowledge /

Lithium battery 18650 and all-polymer battery

29 Dec, 2021

By hoppt

Lithium battery 18650 and all-polymer battery

Let's talk about 18650 and polymer batteries today!

Here, let's take a look at the 18650 battery cell. Its internal structure comprises a positive electrode lithium compound, an electrolyte membrane in the middle, and a negative electrode carbon.

Now standard 2000-3000mAh capacity next-generation batteries, Deronne, Samsung, Panasonic, Sanyo, LG, and other batteries on the market, the internal cathode material has been fully upgraded from the first-generation LiCoO2 lithium cobalt oxide to a ternary material, chemical name It is LiNi-Co-MnO2 nickel cobalt manganese.

Direct benefits: longer service life, safer, better performance. Speaking of this, Prismatic square soft package packaged mobile phone tablet batteries are also made of LiNi-Co-MnO2 nickel-cobalt-manganese material, but it is different from the 18650 Cylindrical boxes.

"All polymer" refers to the use of polymer to form a gel network inside the cell and then inject electrolyte to form an electrolyte.

Although "all polymer" batteries still use liquid electrolytes, the amount is much smaller, significantly improving lithium-ion batteries' safety performance.

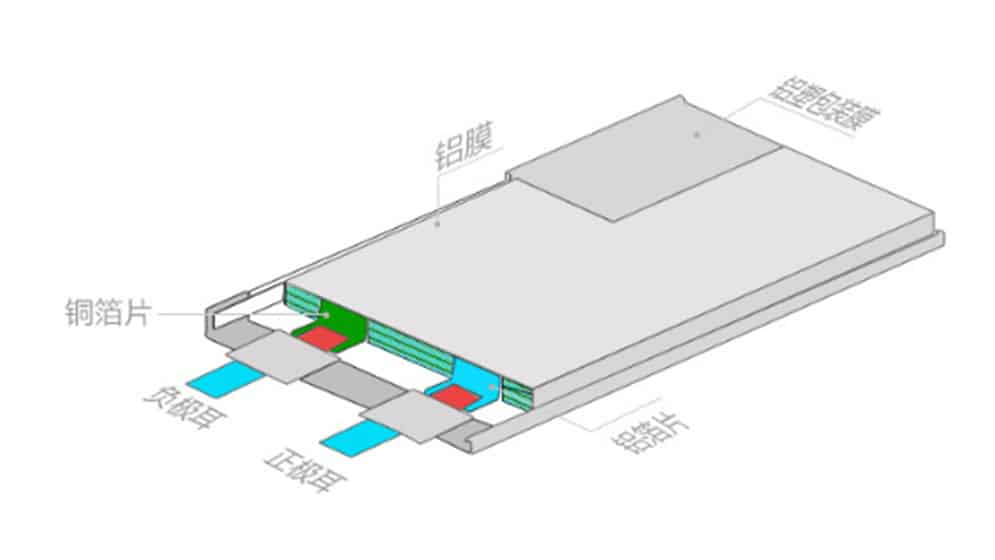

From another aspect, polymer batteries refer to lithium-ion batteries that use aluminum-plastic packaging film as the outer packaging, which is commonly known as soft-pack batteries. This packaging film comprises three layers: the PP layer, Al layer, and nylon layer. Because PP and nylon are polymers, this is called a polymer battery.

Let's compare the advantages and disadvantages of the two:

- Price

The international price of 18650 is about 1USD/pcs. If calculated according to 2Ah, it is everywhere 3RMB/Ah. The cost of polymer lithium batteries is 4RMB/Ah for low-end cottage factories, 5~7RMB/Ah for mid-range, and more than 7RMB/Ah for the mid-to-high end.

- Can it be customized

SONY has always wanted to make lithium-ion batteries like alkaline batteries. There are specific industry standards, just like AA batteries and AA batteries, which are the same worldwide. However, one of the significant advantages of lithium-ion batteries is that they can be designed according to customer needs, and there is no uniform standard. So far, the lithium-ion battery industry only has a standard model of 18650, and the others are based on customers. The size of the demand is designed.

- Security

We know that under extreme conditions (such as overcharge, high temperature, etc.), lithium-ion batteries will have violent chemical reactions inside and produce a lot of gas. The 18650 battery uses a metal shell with a particular strength. When the internal air pressure reaches a certain level, the steel shell will explode, causing a terrible safety accident.

This is why the room where the 18650 battery is tested generally must be protected by layers, and no one can enter during the test. Polymer batteries do not have this problem, even in extreme cases, due to the low strength of the packaging film; as long as the air pressure is slightly higher, it will rupture and will not explode. The worst case is combustion. So in terms of safety, polymer batteries are better than 18650 batteries.

18650 and polymer batteries are both lithium batteries. At present, 18650 is widely used in the market for lithium iron phosphate, lithium manganate, and ternary. The nominal voltage is 3.8V, and the maximum voltage can reach 4.2V when used. Low voltage can reach 2.5V, there is no memory effect, and the use field is relatively wide. The technical strength of domestic production is also capable, and it is suitable for domestic production. The polymer batteries I have seen are mainly soft packs. There are power and capacity types. The material is similar to 18650, except that the 18650 is a stainless steel shell, and the polymer is an aluminum-plastic film shell. It is suitable for industrial production and transportation—power supply.

In general, 18650 and polymer batteries have their advantages, and the quality of the battery depends on the manufacturer's craftsmanship.

Lithium battery 18650 and all-polymer battery

Let's talk about 18650 and polymer batteries today!

Here, let's take a look at the 18650 battery cell. Its internal structure comprises a positive electrode lithium compound, an electrolyte membrane in the middle, and a negative electrode carbon.

Now standard 2000-3000mAh capacity next-generation batteries, Deronne, Samsung, Panasonic, Sanyo, LG, and other batteries on the market, the internal cathode material has been fully upgraded from the first-generation LiCoO2 lithium cobalt oxide to a ternary material, chemical name It is LiNi-Co-MnO2 nickel cobalt manganese.

Direct benefits: longer service life, safer, better performance. Speaking of this, Prismatic square soft package packaged mobile phone tablet batteries are also made of LiNi-Co-MnO2 nickel-cobalt-manganese material, but it is different from the 18650 Cylindrical boxes.

"All polymer" refers to the use of polymer to form a gel network inside the cell and then inject electrolyte to form an electrolyte.

Although "all polymer" batteries still use liquid electrolytes, the amount is much smaller, significantly improving lithium-ion batteries' safety performance.

From another aspect, polymer batteries refer to lithium-ion batteries that use aluminum-plastic packaging film as the outer packaging, which is commonly known as soft-pack batteries. This packaging film comprises three layers: the PP layer, Al layer, and nylon layer. Because PP and nylon are polymers, this is called a polymer battery.

Let's compare the advantages and disadvantages of the two:

- Price

The international price of 18650 is about 1USD/pcs. If calculated according to 2Ah, it is everywhere 3RMB/Ah. The cost of polymer lithium batteries is 4RMB/Ah for low-end cottage factories, 5~7RMB/Ah for mid-range, and more than 7RMB/Ah for the mid-to-high end.

- Can it be customized

SONY has always wanted to make lithium-ion batteries like alkaline batteries. There are specific industry standards, just like AA batteries and AA batteries, which are the same worldwide. However, one of the significant advantages of lithium-ion batteries is that they can be designed according to customer needs, and there is no uniform standard. So far, the lithium-ion battery industry only has a standard model of 18650, and the others are based on customers. The size of the demand is designed.

- Security

We know that under extreme conditions (such as overcharge, high temperature, etc.), lithium-ion batteries will have violent chemical reactions inside and produce a lot of gas. The 18650 battery uses a metal shell with a particular strength. When the internal air pressure reaches a certain level, the steel shell will explode, causing a terrible safety accident.

This is why the room where the 18650 battery is tested generally must be protected by layers, and no one can enter during the test. Polymer batteries do not have this problem, even in extreme cases, due to the low strength of the packaging film; as long as the air pressure is slightly higher, it will rupture and will not explode. The worst case is combustion. So in terms of safety, polymer batteries are better than 18650 batteries.

18650 and polymer batteries are both lithium batteries. At present, 18650 is widely used in the market for lithium iron phosphate, lithium manganate, and ternary. The nominal voltage is 3.8V, and the maximum voltage can reach 4.2V when used. Low voltage can reach 2.5V, there is no memory effect, and the use field is relatively wide. The technical strength of domestic production is also capable, and it is suitable for domestic production. The polymer batteries I have seen are mainly soft packs. There are power and capacity types. The material is similar to 18650, except that the 18650 is a stainless steel shell, and the polymer is an aluminum-plastic film shell. It is suitable for industrial production and transportation—power supply.

In general, 18650 and polymer batteries have their advantages, and the quality of the battery depends on the manufacturer's craftsmanship.